Get a load of this tool: the adjustable wrench

(plus bonus Volvo update)

If you’ve spent any time around old men, tools, folksy wisdom or — god forbid — all three, you’ve no doubt heard about “The Importance Of Having The Right Tool For The Job” (Capitalized. Always capitalized.)

Like a lot of things that get said in a wise grandfatherly tone, it’s true until it isn’t. And so I want to talk about the adjustable wrench — the best wrong tool for the job.

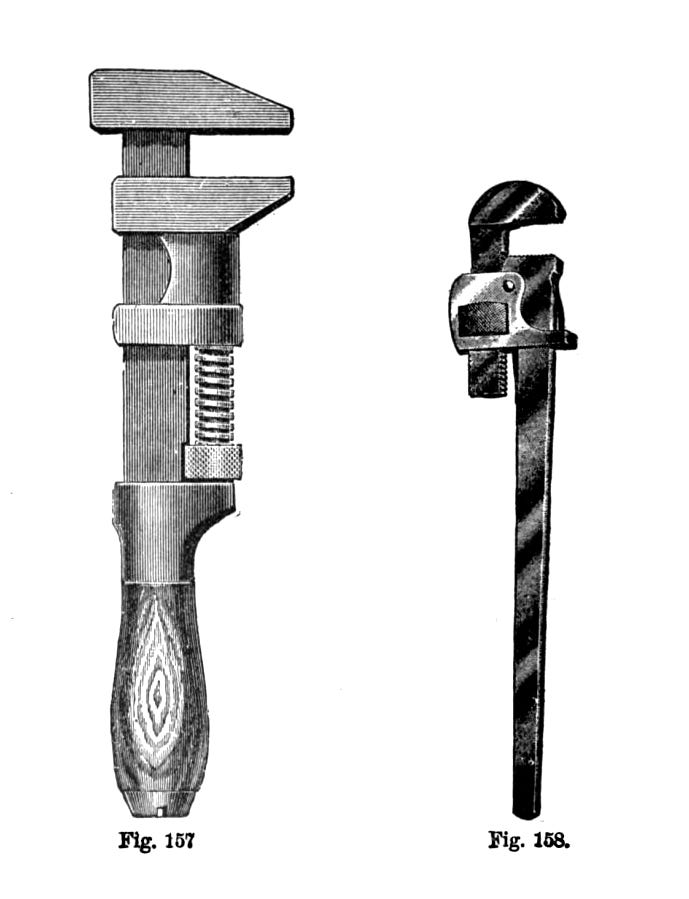

If you own only one tool that isn’t a phillips-head screwdriver, I bet it’s an adjustable wrench — a.k.a. a crescent wrench or (incorrectly) a monkey wrench (which is an older, right-angle adjustable with a largely obsolete design.)

These tools have a well-earned reputation for rounding the corners off of bolts and are almost always a worse option than a properly-sized fixed wrench.

So why have one? Adjustable wrenches are a classic one-size-fit’s all option. They’re cheaper than a set of box-wrenches, they’re lighter to carry around. If you don’t know what you’re about to encounter, they can be an invaluable tool.

When I packed up my tools for a junkyard run this weekend, my biggest adjustable wrench came with me, in case I had to remove any fittings from my junkyard transmission (more on that later).

I’ve used adjustable wrenches to fix leaky faucets, and to turn all kinds of odd-sized fasteners when I had neither the time nor the money to buy a specialized wrench I’d get scant use out of.

So what makes a good adjustable? simply put, lack of slop. Slop (or lash) is the quasi-technical term for the looseness of a mechanical system. If that lower jaw on an adjustable wrench has a lot of slop, the chances that it will slip off a nut or a bolt and round the edges are a lot higher.

See that interface, between the screw thread and the teeth to the rear of the lower jaw? That’s where the magic happens. Or the slop.

A well-built adjustable wrench has a spring pushing down on that screw-thread adjuster in order to take up whatever slop is in the system. And the better built, the less clearance there is between the adjuster and those teeth in the first place.

The fit and finish of the lower jaw in the channeled handle is also going to affect slop. Its a hard thing to eyeball, but the less you can jiggle the jaw with your hand, the better.

There will always be some slop, that’s the nature of the design. But the less the better.

There are a lot of tools that it’s OK to cheap out on. The difference between a $15 Czech-made Wera screwdriver and a $4 honestly-not-sure-where-it’s-made Craftsman is truly marginal even if you make your living with your tools.

(Man, I want those Weras)

An adjustable wrench, though? Pay a little bit more money or hunt around for a deal.

Region of manufacture is often used as shorthand for tool quality, sometimes in a kind of xenophobic way. To some extent that’s garbage — my 20V DeWalt drill is made in China and it’s superb.

But there’s some truth to the idea in as much as brands that want to cheap out on overall quality will usually start by moving production to a market willing to skimp on labor.

Craftsman doesn’t make their tools in the US anymore, and accordingly, my US-made Craftsman adjustable wrench has a lot less slop than their current crop.

But this brings me to something that will likely be a recurring theme when we talk about tools: don’t be afraid to buy used.

Here’s the bargain-basement “Companion” brand wrench that was in my wife’s toolbox when we met above the 1940’s-era Barcalo wrench that belonged to my great-grandfather:

No disrespect to the Companion — that thing fixed quite a bit for us in its day. But the ancient Barcalo, well worn and missing whatever spring it once had to take up slop, still has less lash and play than the Companion.

A good quality, used wrench of moderate size (8-10”) should run you $10-$20 on eBay, less if you encounter one at a garage sale.

And if repair is about reuse and sustainability, no better place to start than with your tools.

An adjustable wrench is the tool to use when you don’t have the right tool. As such, it won’t be used enough to really wear it out.

And, bonus — since monkey and adjustable wrenches really are the calling card of luddite sabotage, (i.e. “throwing a monkey wrench in the works”), any decent one should still be around long enough for your own grandkids to throw in the gears of some Elon Musk-branded techno-futurist nightmare!

Adjustable Wrenches:

Utility - **** They do everything. Not super-well, but everything.

Necessity - ** If you have a wrench set, you can get by without one.

Availability - ***** They are literally everywhere

Bonus track: Volvo rebuild update

So this weekend I schleped out to the wilds of New Jersey to see a junkyard about a transmission.

New Jersey, my home sweet home.

A good buddy of mine, a renowned investigative reporter who also happens to own a truck with enough space to carry a spare transmission and arms strong enough to help lift one, put it this way: “Isn’t this where bad guys come to plot crimes?”

So now I’ve got another transmission.

Ran it up to where the car awaits a new subframe, and for the first time I got a good, daytime look at the damage to the old transmission:

Am I wondering if it’s possible to weld that perfectly triangular puncture shut, and therefore have *two* working transmissions? You’ve read this far, of course I am.

But for now we just have to wait and see, check for more damage as the car slowly gets put back together.

Until next time.